roughing end mill feeds and speeds

Stainless Steel 304 302. Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill Sizes Standard Drill Sizes Drill And Counterbore Sizes.

Solid Carbide End Mills Haimer

Meters Per Minute MPM The cutting speed of the end mill.

. Suppose we are handed the task of roughing out a pocket that has 18-inche corner radii which dictates and end mill no larger than 14-inch in diameter. 31 rows End Mill Speeds And Feeds - TiN Coated Carbide. This system is used in all countries that use the Metric system.

SFM 08 Lowest Range Value. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEMHEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. Increase the cutting speed feed rate until the quality of the parts finish starts to decrease or the part is starting to move from hold downs.

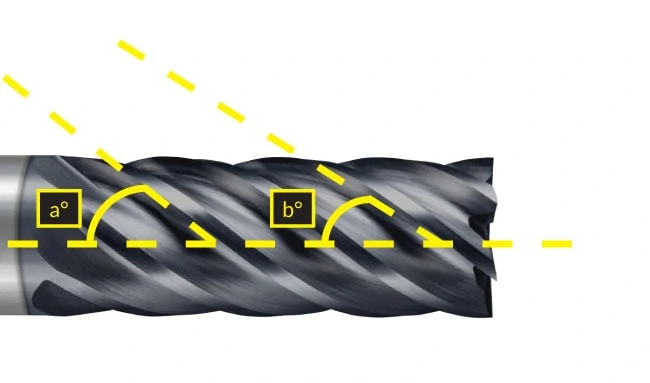

Roughing chip load per tooth. Of chip load chip lead chip lead chip lead chip lead chip lead chip lead chip lead chip lead end mills rpm per tooth rpm per tooth rpm per tooth rpm per tooth rpm per tooth rpm. Specs Tables 4 Flute CGC Gorilla Roughing End Mill variable helix variable pitch Roughing speeds and feeds.

Calculations use the desired tool diameter number of teeth cutting speed and cutting feed which should be chosen based on the specific cutting conditions including the workpiece material and tool material. Over 100000 Tools Industrial Supplies In Stock. 28 rows speeds and feeds speeds and feeds for boring tools material plastic magnesium aluminum.

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill. Now we need feeds and speeds. The CGC Gorilla Sasquatch is recommended for roughing all long chip materials.

Ad Recommendations For Any Material Grade Or Machining Application. Our G-Wizard Feeds and Speeds Calculator has special features to help with plunge milling. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

SMM SFM X 3048. SFM and Feed For AD between 025 to 05 of Tool Dia. Higher range of recommended surface speeds should be used For Greater Radial Depths-of-Cut.

Speed and feeds for high speed Steel and Cobalt End Mills. This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure. PREMIUM COBALT MILL SPEED FEED Multi-Flute - Side Cutting - Roughing - HSS-C08 End Mills CHARTS Aluminum Aluminum Alloys Material Hardness Diameter 14 516 38 12 58 1116 78 1-18 1-14 1-38 1-34 Carbon Steels Alloy Steels Tool Steels Carbon Steels Alloy Steels Tool Steels.

Lower range of recommended surface speeds should be used For Slotting Applications. Designed to Mill Hardened Steels up to 55Rc. FEEDS SPEEDS FOR ALL Tech Line - Normal Rougher 450 00050016 0019 0025 0030 SFM WOC d 1 xx050 500 10 WOC 10 SFM 1350 IPT WOC 10 10 18 IPT multiplier IPT 0026 x 18 0047 IPT 0047 If surface finish is the priority use IPT from table with no adjustment for chip thinning.

Roughing End Mills - Cobalt and High Speed Steel. Depending on surface specs its a great finisher too. Just so I am clear on the recommendations when you say 10 of the diameter of a regular end mill or 100 of the diameter of a roughing end mill do you mean that if I am using the full diameter of the end mill say a 1 diameter my lengthdepth of cut should be 0100 for regular an 1000 for roughing.

Then decrease speed by 10. In Stock- Same Day Shipping. Chip load x Number of flutes.

Ad 5 Flute Variable Helix Design for Improved Slotting and Roughing. Tipped End Mill 13642 48-005 na na 1 na na na 12 Straight V Carbide Tipped End Mill 13564 48-072 na na 2 na na na 14 Upcut Carbide End. Radial Side Depth of Cut.

Millimeters Per Revolution MMPR Feed rate of the cutter each revolution of the cutter. End Mill Speed Feed Calculator. Lets work through an example that shows the strengths of plunge milling.

TAPERED END MILLS HIGH SPEED STEEL FEED PER TOOTH ROUGHING AND FINISHING Material. Ad Shop Online Save Big. For Lighter Radial Depths-of-Cut.

Cart Shopping Cart Toggle navigation. Speeds SFM should be reduced approximately 20 of lowest range value Above recommendations are to be used when axial depth-of-cut does not exceed 1 12. Solid Carbide Cutting Tools Designed For Closer Tolerances A Longer Lifespan.

Use SFM for 10 radial width of cut. This will adjust the feedrate if less than the tool rad. 78 to 1 Aluminum 6061.

Normally a 20 reduction in effective horsepower is used. End Mill Speed Feed HSS M42 Cobalt. Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End.

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. Speed speed speed speed speed speed speed speed speed 5-10 sfm feed 10-15 sfm feed 15-20 sfm feed 20-40 sfm feed 40-60 sfm feed 60-80 sfm feed 80-100 sfm feed 100-200 sfm feed 200-600 sfm feed dia. In the metric system the feed rate of the cutter can be calculated for each revolution of the cutter.

Multiple Uses Of Chamfers Multiple Cost Saving Canning

Speed Feed Recs Melin Tool Company

Circular Interpolation Circular End Mill Linear

8 Ways You Re Killing Your End Mill In The Loupe

End Mill For Aluminium 6mm Diameter 3 Flute Un Coated Micro Grain Carbide Associated Production Tools

Freud 87 308 3 Piece Fine Detail Cnc Router Bit Set Cnc Router Bits Cnc Router Router Bit Set

8 Ways You Re Killing Your End Mill In The Loupe

Solid Carbide Square End Mills 2 Flute Down Cut Uk

3 Flute Carbide End Mill For Aluminium 4mm Diameter 45 Helix Associated Production Tools

What To Know When Selecting An End Mill End Mill The Selection Machining Process

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

End Mill An Overview Sciencedirect Topics

End Mills The Essential Beginners Guide

Osg Taps End Mills Drills Indexable Composite Tooling Diamond Coating Die Products Hss Co Roughing

8 Ways You Re Killing Your End Mill In The Loupe

3 Flute Carbide Roughing End Mill For Aluminium 8mm Diameter Associated Production Tools

Roughing End Mill 20mm Diameter 4 Flute Altin Coated Micro Grain Carbide 45hrc Associated Production Tools

Solid Carbide 2 Flute Down Cut Spiral Router Bits

Gmg12 6 Flute 12mm V7 Plus Carbide End Mill Cutwel Milling Tools Cutwel Ltd